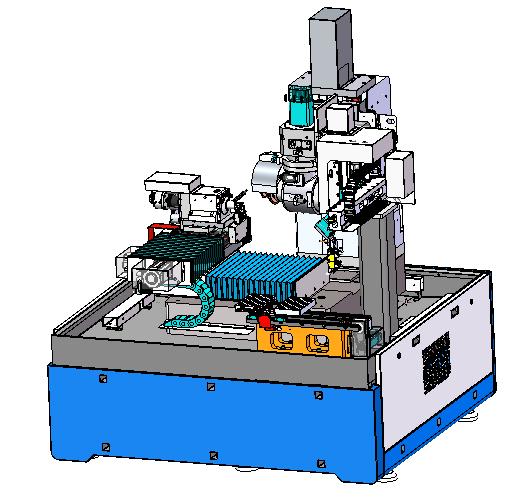

GM5X-E 5-aks CNC Manje machin

Dyagram prensipal estrikti nan machin

Dimansyon aplikasyon

Machin sa a pwodui kouto fraisage fen ak egzèsis, apwopriye pou pwosesis alyaj difisil ak materyèl asye gwo vitès.

Sik fabrikasyon zouti ak regrinding

Estanda fen kouto fraisage: slotting, pwosesis pèl tounen, Front kwen fanm k'ap pile, kwen anba fanm k'ap pile, Digitalize, Regrinding.

Egzèsis estanda: fant, dyamèt ekstèn redwi, kwen devan fanm k'ap pile, dijitalize, Regrinding.

1. espesifikasyon teknik

| № | Kontni | Egzijans | Nimewo | Inite |

| 1.1 | Dimansyon pyès travay la | |||

| 1.1.1 | Longè blocage | ≤ | 300 | mm |

| 1.1.2 | Blocage dyamèt | ant | 2-20 | mm |

| 1.1.3 | Manje longè | ≤ | 180 | mm |

| 1.1.4 | Manje dyamèt | ant | 2-12 | mm |

| 1.2 | Manje koton | |||

| 1.2.1 | Kalite kondwi | Egzat | kondwi dirèk | - |

| 1.2.2 | Pouvwa | pouvwa nominale | 7.1 | kW |

| 1.2.3 | Refwadisman | Egzat | Lwil oliv refwadi | - |

| 1.2.4 | Kontwòl vitès nan wou fanm k'ap pile | Egzat | Stepless-vitès | - |

| 1.2.5 | Vitès | ant | 0-10000 | rpm |

| 1.2.6 | Kantite axe fanm k'ap pile tèt | Egzat | 2 | pcs |

| 1.3 | Manje wou | |||

| 1.3.1 | Dyamèt | ≤ | 150 | mm |

| 1.3.2 | Kantite maksimòm wou fanm k'ap pile pou chak file | ≤ | 4 | pcs |

| 1.3.3 | Manje wou dyamèt file koton | Egzat | 25 | mm |

| 1.3.4 | Pwogram kontwole rezèv awozaj | Egzat | Wi | - |

| 1.3.5 | Kantite bouch awozaj | ≥ | 3 | pcs |

| 1.4 | Materyèl blocage sistèm | |||

| 1.4.1 | Blocage sistèm | Egzat | Idwolik, otomatik | - |

| 1.4.2 | Sere kole | Egzat | SCHAUBLIN W20 | - |

| 1.4.3 | Kalite kondwi | Egzat | kondwi dirèk | - |

| 1.5 | Paramèt aks | |||

| 1.5.1 | Kalite | Egzat | lineyè | - |

| 1.5.2 | Vwayaj aks X | ≤ | 340 | mm |

| 1.5.3 | Z-aks vwayaj | ≤ | 335 | mm |

| 1.5.4 | Vwayaj aks Y | ≤ | 170 | mm |

| 1.5.5 | Rezolisyon aks XYZ | Egzat | 0.0001 | mm |

| 1.5.6 | Vitès aks XYZ | ≤ | 15 | m/min |

| 1.5.7 | A-aks vwayaj | ≤ | 360 | degre |

| 1.5.8 | A-aks rezolisyon | Egzat | 0.0001 | degre |

| 1.5.9 | Vitès A-aks | ≤ | 500 | rpm |

| 1.5.10 | B-aks vwayaj | ± | 180 | degre |

| 1.5.11 | Vitès B-aks | ≤ | 20 | rpm |

| 1.6 | Chajman ak dechaje sistèm | |||

| 1.6.1 | Chajman ak dechaje sistèm | Egzat | Bras robo kalite bastengal | - |

| 1.6.2 | Kantite plato | Egzat | 2 | pcs |

| 1.6.3 | Otomatik chaje ak dechaje travay-moso dyamèt | Ant | 3-16 | mm |

| 1.6.4 | Otomatik chaje ak dechaje longè moso travay | ≤ | 90 | mm |

| 1.6.5 | Maksimòm kantite pyès | ≤ | 300 | pcs |

| 1.6.6 | Lojisyèl | Egzat | Wi | - |

| 1.7 | Lòt konpozan | |||

| 1.7.1 | Kapasite pou detekte pyès sou machin zouti | Egzat | Wi | - |

| 1.7.2 | Sistèm lubrification otomatik santralize | Egzat | Wi |

|

| 1.7.3 | Tricolor siyal lanp | Egzat | Wi | - |

| 1.8 | Si ou vle | |||

| 1.8.1 | Ekipman separasyon vapè lwil oliv | Egzat | Si ou vle | - |

| 1.9 | Kontwòl | |||

| 1.9.1 | Sistèm kontwòl | Egzat | Newcon | - |

| 1.9.2 | Operasyon panèl | Egzat | Ekran taktil | - |

| 1.9.3 | Aks kontwòl dijital | Egzat | Wi | - |

| 1.9.4 | Ekspozisyon koulè | Egzat | Wi | - |

| 1.9.5 | Gwosè ekspozisyon | Egzat | 19 | pous |

| 1.10 | Zouti fanm k'ap pile modil lojisyèl | |||

| 1.10.1 | Kouto fraisage senp | Egzat | Wi | - |

| 1.10.2 | Egzèsis senp | Egzat | Wi | - |

| 1.10.3 | Sonde mòd deteksyon otomatik | Egzat | Wi | - |

| 1.11 | Ekipman paramèt elektrik | |||

| 1.11.1 | Voltage | Egzat | 380±10% | V |

| 1.11.2 | Frekans | Egzat | 50±10% | Hz |

| 1.11.3 | Pouvwa | ≤ | 25 | KW |

| 1.12 | Dimansyon | |||

| 1.12.1 | Longè | ≤ | 1 820 | mm |

| 1.12.2 | Lajè | ≤ | 2 650 | mm |

| 1.12.3 | Wotè | ≤ | 2 300 | mm |

| 1.12.4 | Kalite | ≤ | 4 300 | kg |

2. Lis konfigirasyon estanda

| № | Kontni | Modèl | Mak | Nimewo | ||

| 2.1 | Zouti machin | |||||

| 2.1.1 | Konfigirasyon X-aks | |||||

| 2.1.1.1 | - Vis baton | Customized | NSK | 1pcs | ||

| 2.1.1.2 | - Rail | 1×MR25-A2-760-20-20-G2-V2+BRK+SOSPL | SCHNEEBERGER | 2pcs | ||

| 2.1.2 | Y-aks konfigirasyon | |||||

| 2.1.2.1 | - Vis baton | Customized | NSK | 1pcs | ||

| 2.1.2.2 | - Rail | 1×MR35-C2-600-20-20-G2-V2+MRK | SCHNEEBERGER | 2pcs | ||

| 2.1.3 | Z-aks konfigirasyon | |||||

| 2.1.3.1 | - Vis baton | Customized | NSK | 1pcs | ||

| 2.1.3.2 | - Rail | 1×MR25-A2-850-20-20-G2-V2+BRK+SOSPL | SCHNEEBERGER | 2pcs | ||

| 2.1.4 | A-aks konfigirasyon | |||||

| 2.1.4.1 | - Angle ankode | ECN113 | HEIDENHAIN | 1pcs | ||

| 2.1.4.2 | - Motè kondwi dirèk | MSP-1000-2-002-158 | HIWIN | 1pcs | ||

| 2.1.5 | B-aks platin | Customized | GuTian | 1pcs | ||

| 2.1.6 | Eman pèmanan doub tèt elektrik filet | Rated pouvwa 7.1KW | Chuangyun | 1 pcs | ||

| 2.1.7 | Twa aks bastengal manipulateur | - | Chuangyun | 1pcs | ||

| 2.1.8 | Plato | 148-LP-D4 | Chuangyun | 2pcs | ||

| 2.1.9 | Plato | 148-LP-D6 | Chuangyun | 2pcs | ||

| 2.1.10 | Plato | 148-LP-D8 | Chuangyun | 2pcs | ||

| 2.1.11 | Clamping machwè | D0.5-3.2/D3.0-7.0/D7-13 | Chuangyun | 1 ansanm | ||

| 2.1.12 | Segondè presizyon V-blòk | (3-5) | Chuangyun | 1pcs | ||

| 2.1.13 | Segondè presizyon V-blòk | (5-7) | Chuangyun | 1pcs | ||

| 2.1.14 | Segondè presizyon V-blòk | (6-12) | Chuangyun | 1pcs | ||

| 2.1.15 | Collet | D4W20 (80-00004) | SCHAUBLIN | 1pcs | ||

| 2.1.16 | Sonde | TS150 | HEIDENHAIN | 1pcs | ||

| 2.1.17 | Manje wou baton (long) | 119×∅31.75×∅96mm | Chuangyun | 1pcs | ||

| 2.1.18 | Manje wou baton (kout) | 87×∅31.75×∅96mm | Chuangyun | 1pcs | ||

| 2.1.19 | È kondisyone | - | YUEDE | 1pcs | ||

| 2.1.20 | Tricolor siyal lanp | DC24V | Schneider | 1pcs | ||

| 2.1.21 | Debimèt | SI5000 | IFM | 1pcs | ||

| 2.1.22 | Kondwi ekipman pou pouvwa espesifik | 15KW | NEWCOM | 1pcs | ||

| 2.1.23 | Gwoup tiyo elektwomayetik | M4GE280R-CX-E20D-5-3 | CKD | 1 ansanm | ||

| 2.1.24 | X, Y, Z-aks sistèm lubrification otomatik | - | Taiwan | 1 ansanm | ||

| 2.2 | CNC konfigirasyon sistèm | |||||

| 2.2.1 | BOXPC | IMPC00S/P1 | Newcon | 1pcs | ||

| 2.2.2 | Pouvwa filtre | AGOFIL024A | Newcon | 1pcs | ||

| 2.2.3 | Pouvwa filtre | AGOFIL001S | Newcon | 1pcs | ||

| 2.2.4 | Rezistans | AGORES008 | Newcon | 1pcs | ||

| 2.2.5 | Sistèm prensipal ekipman pou pouvwa | MDLL3015N00AN0I | Newcon | 1pcs | ||

| 2.2.6 | Servo chofè | MDLUX021B1CAN0I | Newcon | 4pcs | ||

| 2.2.7 | B-aks servo motè | ZLS1002-H60-D3M1-NNSB-D16E40 | Newcon | 1pcs | ||

| 2.2.8 | A-aks motè | MSP-1000-2-002-158 | HIWIN | 1pcs | ||

| 2.2.9 | Y-aks servo motè | ZLS1454-H30-DCM1-SNSB-D24E50 | Newcon | 1pcs | ||

| 2.2.10 | X/Z-aks servo motè | ZLS1153-H30-D3M1-NNSB-D19E40 | Newcon | 2pcs | ||

| 2.2.11 | U/W aks servo chofè | ZLS0754-H60-D2M1-SNSB-D14E30 | Newcon | 2pcs | ||

| 2.2.12 | V-aks servo motè | ZLS0754-H60-D2M1-SNSB-D14E30 | Newcon | 1pcs | ||

| 2.2.13 | Kouple | EX-1100 | Newcon | 1pcs | ||

| 2.2.14 | Antre | EX-210H | Newcon | 2pcs | ||

| 2.2.15 | Sòti | EX-310H | Newcon | 2pcs | ||

| 2.2.16 | Modil opinyon analòg | EX-4054 | Newcon | 1pcs | ||

| 2.2.17 | Terminator | EX-TRE01 | Newcon | 1pcs | ||

| 2.2.18 | Operasyon panèl | IMOP4106/H | Newcon | 1pcs | ||

| 2.2.19 | NCK | IM8+ | Newcon | 1pcs | ||

| 2.2.20 | NCK | IMSO100006 | Newcon | 1pcs | ||

| 2.2.21 | NCK | IMSO100008 | Newcon | 1pcs | ||

| 2.2.22 | NCK | IMSO100012 | Newcon | 1pcs | ||

| 2.2.23 | NCK | IMPA100586 | Newcon | 1pcs | ||

| 2.2.24 | NCK | IMSO100373 | Newcon | 1pcs | ||

| 2.2.25 | NCK | IMSO100375 | Newcon | 1pcs | ||

| 2.2.26 | NCK | IMSO100335 | Newcon | 1pcs | ||

| 2.2.27 | NCK | IMSO100519 | Newcon | 1pcs | ||

| 2.2.28 | NCK | IMSO100392 | Newcon | 1pcs | ||

| 2.2.29 | NCK | IMSO100331 | Newcon | 1pcs | ||

| 2.2.30 | NCK | IMSO100535 | Newcon | 1pcs | ||

| 2.2.31 | NCK | IMSO100520 | Newcon | 1pcs | ||

| 2.2.32 | NCK | IMSO100560 | Newcon | 1pcs | ||

| 2.3 | Estanda konfigirasyon zouti fanm k'ap pile lojisyèl | |||||

| 2.3.1 | Senp kouto fraisage | Chuangyun pwòp tèt ou-devlope | 1pcs | |||

| 2.3.2 | Senp egzèsis | Chuangyun pwòp tèt ou-devlope | 1pcs | |||

| 2.3.3 | Tcheke kolizyon 3D ak simulation machin 3D | Chuangyun pwòp tèt ou-devlope | 1pcs | |||

| 2.3.4 | Simulation zouti 3D | Chuangyun pwòp tèt ou-devlope | 1pcs | |||

| 2.3.5 | Sonde deteksyon otomatik | Chuangyun pwòp tèt ou-devlope | 1pcs | |||